Distillery

Breathing the soul into Houzan

Inside the distillery, our team of craftspeople take the sweet potatoes and rice which are full of vitality from the fields and imbue them with the deliciousness that makes people happy. We continue do the hard work to be worthy of the land.

Nishi Shuzo’s shochu is for the purpose of making people happy.

If it doesn’t make you happy from the bottom of your heart, it can’t be called Houzan.

We hold that belief strong in every step of our work, from the finer details to the pursuit of flavor and quality control.

Every member of our team works on all steps of the process, from trimming the sweet potatoes to attending to our customers.

This is because we think it is impossible to fulfill any responsibilities at the distillery without knowing the entire shochu story, starting with the moment shochu is born until finally seeing the smiles of our customers.

We also have a rice storehouse, which is unusual for a shochu distillery, where we keep the entire season’s worth of brown rice, removing only the necessary daily amount for polishing and preparation.

All of this is in our pursuit of a higher standard of deliciousness and greater customer satisfaction.

We believe that making a firm promise is the foundation for delivering true flavor.

Please drink the Houzan that we make and taste for yourself the deliciousness that is born from our principles.

Distillery Manager / Kenji Tanogashira

-

Processing the sweet potatoes

When the sweet potatoes arrive at the distillery during harvest season, the first thing we must do is sort and prep them.

This is known as trimming. Everyone holds a knife and removes any bruises or areas that are unnecessary for making shochu.

By prepping each potato by hand, we can get a feel for the ingredients directly. -

Seigiku/Making koji

First, we take the time and effort to carefully sprinkle koji mold onto freshly steamed rice. It is a delicate process involving the work of microorganisms.

The next day, the koji is transferred to a specialized room called the koji muro, which is designed for optimal temperature and ventilation, and left for a day.

This is the koji making process.

It is said that koji is the most important step of the shochu brewing process (followed by moto/yeast, and then the actual brewing and distillation).

-

Fermentation

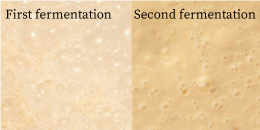

The next step of the imo shochu production process is the fermentation, known as making moromi or shikomi and carried out in two stages. First, the koji rice is mixed with water and yeast.

The koji enzymes break down the starches into sugar, which the yeast converts into alcohol.

This stage is known as ichijimoromi.

Then, the main ingredient of sweet potato is added for the second stage, nijimoromi.

The addition of the sweet potato starches and creation of alcohol is known as “multiple parallel fermentation,” resulting in a highly concentrated moromi mash with complex flavor components.

The carbon dioxide released as a byproduct of alcohol fermentation causes the mash to bubble and circulate from within. -

Distillation

After the second stage of fermentation is completed, the moromi is distilled in order to extract the alcohol and volatile compounds.

Distillation is the process of heating the mash to vaporize it, then cooling the vapor to return it to liquid. The two methods of distillation are known as normal/atmospheric pressure distillation or vacuum/reduced pressure distillation.

The resulting clear liquid that is collected is known as genshu, undiluted raw distillate.

Distilling only once makes it possible to preserve most of the flavor components while simultaneously extracting a high concentration of alcohol. -

Storage

The undiluted genshu, with an alcohol content of about 35~45% by volume, is then aged for several months.

The process of mellowing and calming the newly-born shochu can only be accomplished by time.

The matured shochu that wakens from its quiet slumber has different characteristics depending on how long and under what conditions it was aged. -

Bottling/Shipment

The matured genshu is then filtered, blended, and adjusted for alcohol content as necessary before being bottled as a final product.

Although most labeling is done by machine, some products are individually hand-labeled by our craftspeople.

Finally, the product of so much time and the work of so many people’s hands is complete, and our shochu is ready to be loaded onto trucks and delivered to our customers via wholesalers and retailers across the land.