The commitment of craftspeople

Sake is the tiny work of microorganisms, crafted by human hands.

We carefully communicate with these ingredients gifted to us from nature,

and watch over them gently, sometimes strictly, to ensure optimal fermentation.

Seimai/Polishing the rice

We determine the rice polishing ratio (seimaibuai) that brings out the best qualities of the rice, neither too much nor too little.

Senmai/Washing the rice

Gently wash the rice, as if polishing the grains with water.

Shinseki/Soaking the rice

Ensuring the optimal water absorption rate, which differs from rice to rice, while soaking it in the naturally filtered groundwater of Kagoshima.

Mushimai/Steaming the rice

The freshly steamed rice will be used for making koji, the yeast starter, and the fermentation.

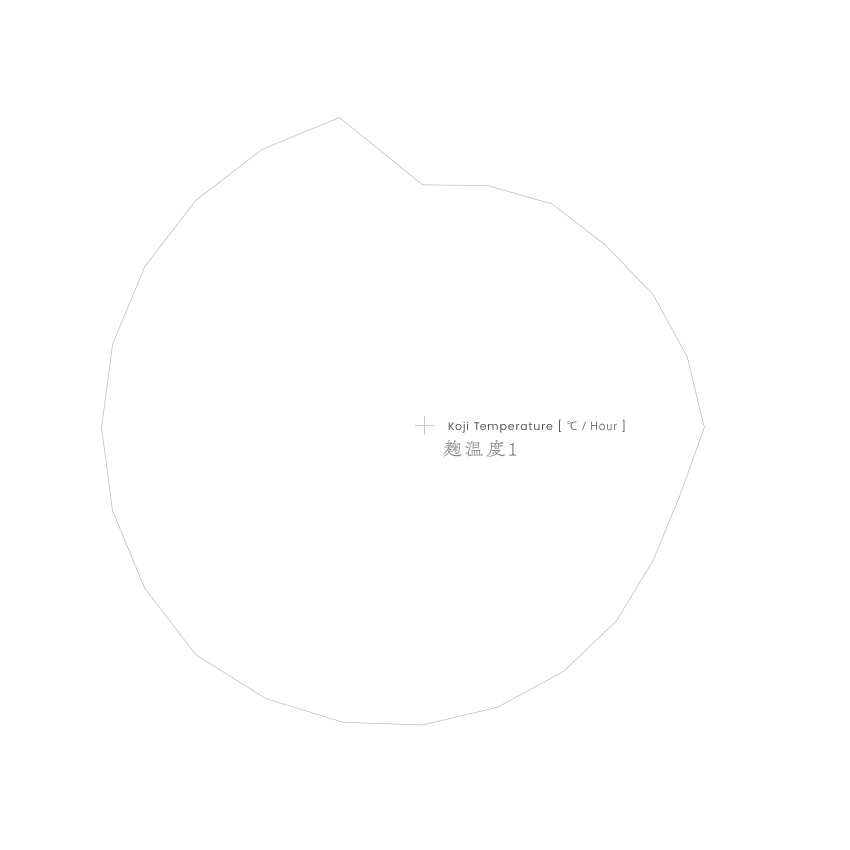

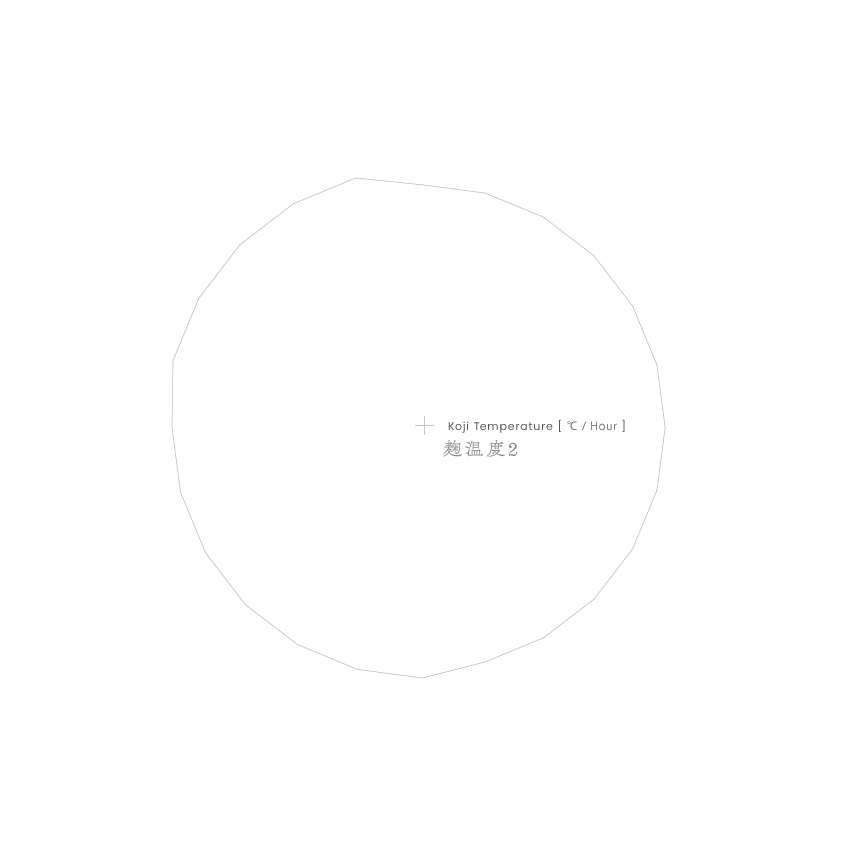

Seigiku/Making koji

Koji is brought to life by being sprinkled over steamed rice.

It is said that koji is the most important step of the sake brewing process (followed by shubo, and then the actual brewing).

We guide the propagation and cultivation of the koji to match our ideal enzyme concentration.

Shubo (moto)/Yeast starter

The shubo is the initial brewing stage, where yeast is added to steamed rice, water, and koji to promote fermentation.

Our yeast is cultivated by our craftspeople with the utmost care.

Dan jikomi/Stages of mashing

The standard for sake brewing is a three-stage preparation brewing process known as sandan jikomi.

On the first day is hatsuzoe,

the second day is a rest day known as odori,

the third day is nakajikomi,

and the fourth and final day is called tomejikomi.

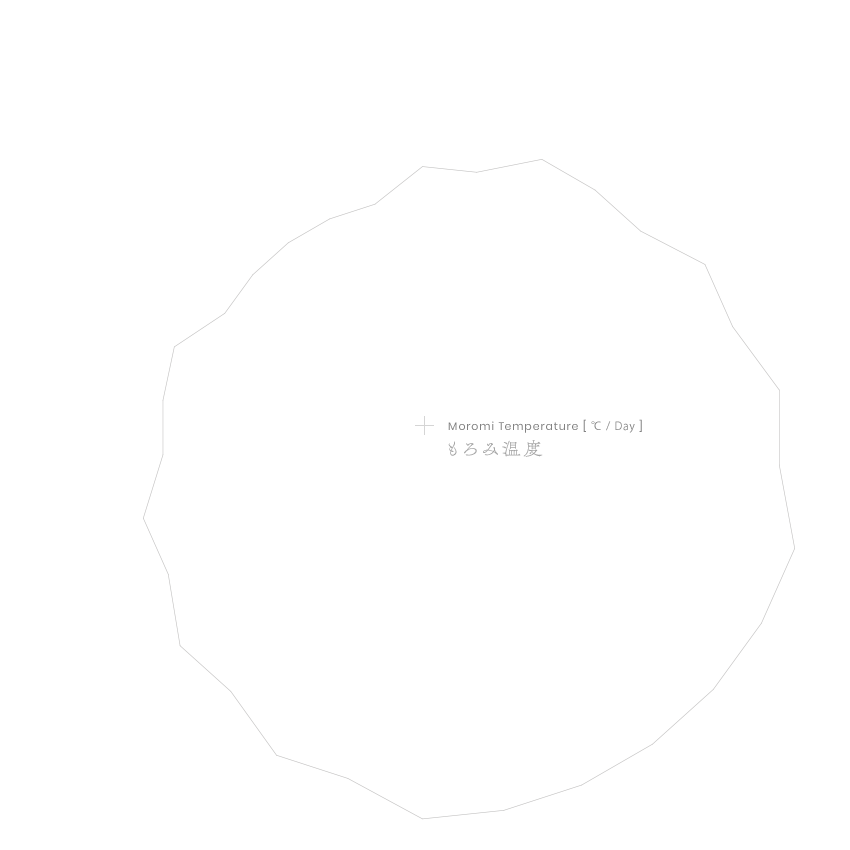

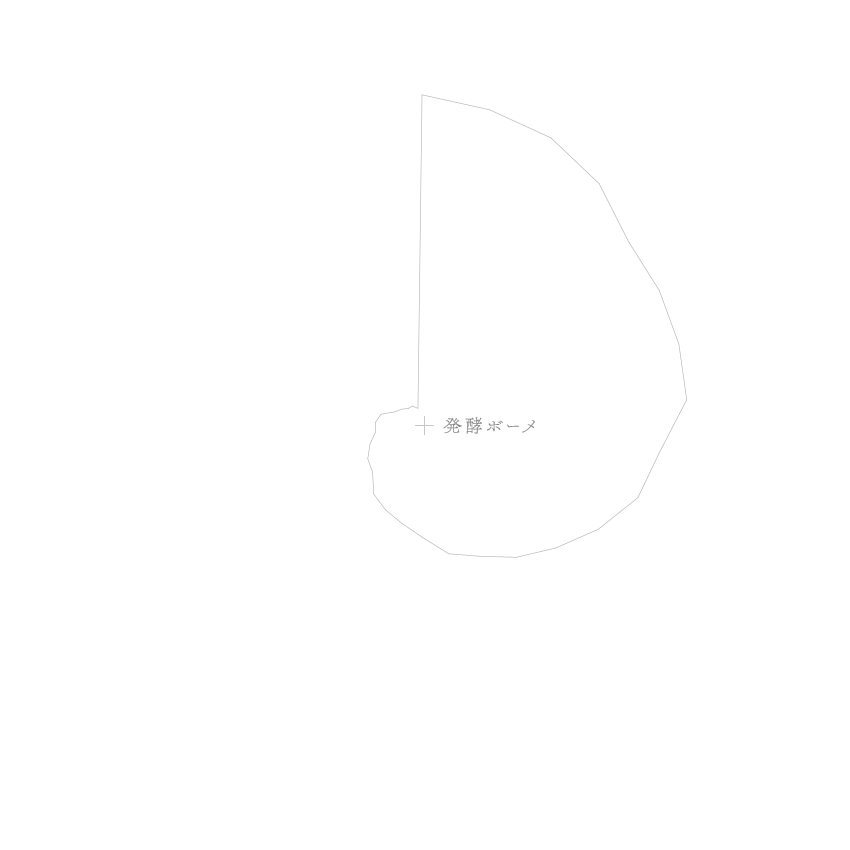

Moromi/Fermentation mash

As the koji breaks the rice starches down into sugar, the yeast begins its fermentation work. After all the ingredients are added in the 4 days of sandan jikomi, the fermentation continues for approximately one month, with our craftspeople keeping a close eye on the moromi until it finishes.

Joso (shibori) /Pressing

The finished fermentation is pressed, separating it into namazake (unpasteurized sake) and the leftover sake kasu (sake lees).

Binzume, Hiire / Bottling, pasteurization

The freshly squeezed namazake is bottled and pasteurized at the peak timing, with the best flavor and aroma preserved inside the bottle.

The moromi fermentation requires delicate temperature control.

We must meticulously oversee the temperature of the koji as it converts the starches in the rice to sugar,

as well as the temperature of the fermentation as the yeast converts the sugars into alcohol.

The graphic above illustrates how the temperatures change on a daily basis.